Robotic arms are at the heart of modern production and manufacturing have changed the norms in a way previously thought to be not possible. They are able to combine the highest level of safety, precision and effectiveness. Robots are amazing mechanical devices which have become indispensable in many industries around the world. They were developed to reduce operating costs and maintain high quality standards. When integrating robotic arms in production lines, companies are not just cutting costs but also revolutionizing workplace safety and productivity. Discover how these revolutionary robotics have changed the landscape of industrial production.

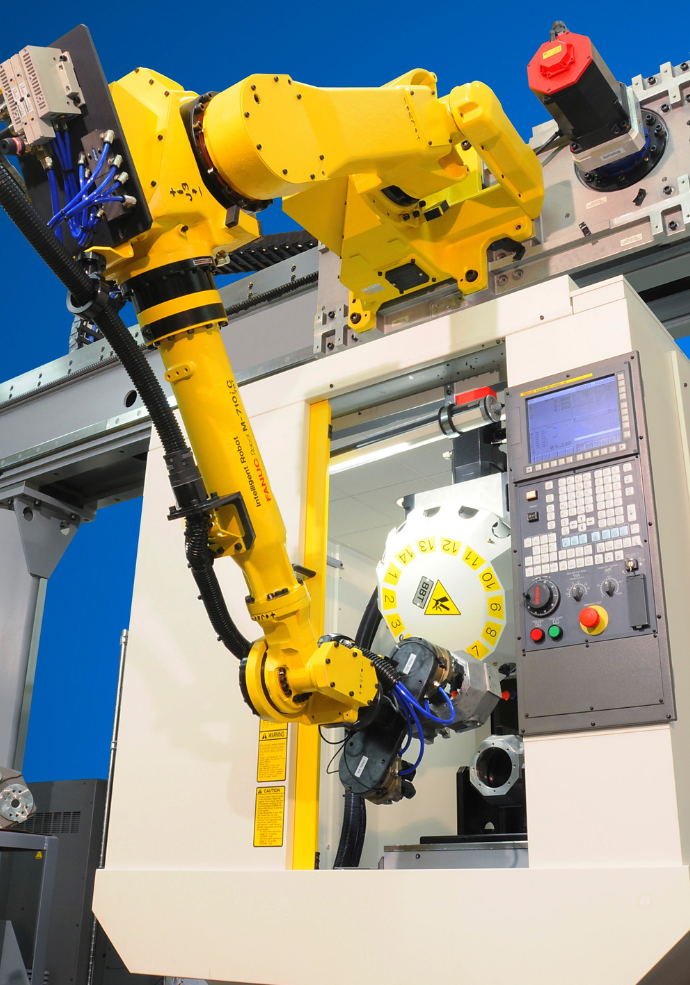

Image credit: automatedsolutions.com.au

The driving force behind the increase in global robotic arm use is the efficiency of costs. The owners of factories are under constant pressure to reduce workplace injuries, limit production errors, and cut down on costs. Robotic arms are specifically designed to solve these issues. In contrast to human workers, robotic arms are able to perform routine tasks with precision which eliminates costly errors and reducing waste of raw materials. For instance, in high-volume industries like automotive manufacturing, robotic arms execute precise welding and part positioning making sure that the assembly is perfect each time. This ensures significant savings since fewer imperfections mean less rework, waste and work.

Security is a key element to the advancement of robotic arms. Numerous manufacturing jobs like handling hazardous materials or operating large machinery pose risks to workers. Utilizing robot arms, companies can eliminate workers from potential danger zones. This lowers the risk of injuries at work. Robotic arms are comprised of a variety of movable joints that replicate the human arm’s functionality. They operate without danger of injury. With hand end effectors that allow these machines to complete tasks that can be dangerous for humans, like spinning or welding.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms are able to be used for diverse tasks, from automotive assembly to electronic production. They can carry out complex tasks with unparalleled precision, such as machine tool tending and painting. In warehousing and storage, robotic arms have revolutionized palletizing by making it easier to load products onto pallets using precision and speed. Automation does not just increase efficiency however, it also improves reliability because robot arms can operate without a lot of fatigue.

Cobots are a brand new type of robots that work together with humans. As opposed to traditional industrial machines that are limited to isolated cells, cobots outfitted with robotic arms are created for safe, seamless interaction with humans. Cobots that have robotic arms are able to perform repetitive or heavy lifting tasks in factories, which allows human workers to concentrate on more complex responsibilities. Collaboration increases productivity as well as ensures a safe work environment, as cobots can be programmed to change or stop their actions when a person is near.

The significance of robotic arms goes beyond safety and efficiency into the very foundation of manufacturing today. The ability robotic arms to carry out tasks with great accuracy, such as welding, material handling or assembly have made them vital in fields where safety is the top priority. In automotive production such as assembly the robot arm is able to rotate and place parts in the assembly process to ensure that they are aligned perfectly without the requirement for human intervention. Similar to electronics, robot arms handle delicate components using care, minimizing the risk of damage and enhancing output quality.

As industries continue their evolution robotic arms’ importance will grow. They will be a key element in the future of manufacturing due to their ability to reduce costs, improve safety and adapt to different tasks. Combining cutting-edge technology with human creativity, robot arms are more than just tools. They’re partners who drive the pace of innovation and are changing how we create our world.